On March 19-22, 2024, we participated in the 19th International Fair of Welding Technologies and Equipment as part of the INDUSTRIAL SPRING event in Kielce, Poland. At a joint stand with our business partner Technika Spawalnicza from Poznań, we presented resistance welding equipment and technology.

TAYLOR Studwelding Systems Limited is a British specialist in the production of stud welding equipment, which has been supplying industrial companies in Europe and around the world for 35 years.

As a result of fruitful cooperation with TAYLOR, we have become the exclusive distributor of this brand in Poland. Our offer includes a wide range of devices and accessories for welding studs and automated CNC stations, designed and built by our company based on TAYLOR systems.

On October 10 and 11, 2023, we took part in the 5th International Seminar entitled Progress and innovations in welding technologies and alternative techniques organized by the Upper Silesian Institute of Technology ŁUKASIEWICZ in Katowice.

We presented issues related to the automation of processes carried out in welding machines and technological lines designed and manufactured by our company.

On May 30 – June 2, 2023, the Mach-Tool Fair in Poznań was held as part of the ITM Industry Europe event. It is here that the latest achievements in the field of metalworking, including resistance welding, are presented every year. As every year, together with our partner Technika Spawalnicza from Poznań, we presented our specialized welders, including lines for the production of fencing panels and welding stations for the automotive industry.

We are always happy to support players associated with the STS Sokół Smolec club. This time we helped in the purchase of a mowing tractor. We wish the players only won matches on the perfectly mowed grass of the club pitch!

On March 28-31, 2023, as part of the INDUSTRIAL SPRING, the International Fair of Technologies and Equipment for Welding took place in Kielce. SMOLTECH was present at the stand of our partner Technika Spawalnicza from Poznań to jointly present the offer in the field of resistance welding.

Another football season has started. The SOKÓŁ SMOLEC Sports Association in Smolec can always count on our support. This year, we financially support the purchase of a tractor for mowing the club pitch and as usual we root for all the teams, especially Sneakers and Seniors, who wear T-shirts with the SMOLTECH logo in the 2023/2024 season.

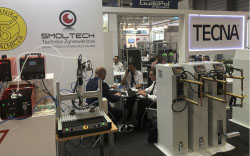

On October 18-20, 2022, together with our partner Technika Spawalnicza from Poznań, we presented TECNA resistance welding machines and other devices related to metal welding technology at the 8th International Welding Fair ExpoWELDING in Katowice.

In the spring of 2022, together with our partner, Technika Zgrzewalnicza from Poznań, we participated in two industry events: the 17th International Fair of Technologies and Equipment for Welding in Kielce and the International ITM Industry Europe Fair in Poznań.

In December 2021, we took part in the nationwide social project – Szlachetna Paczka, organized by the Spring Association, whose main goal is material and mental help for families and people in difficult life situations.

In autumn 2021 SMOLTECH took patronage over the recording and release of the jubilee album of the Wrocław Mizia & Mizia Blues Band. The album “Dzień na minus, Dzień na blues” was created on the occasion of the 20th anniversary of the band’s activity. We keep our fingers crossed for a successful tour promoting the album and we wish the band further success on the music scene.

On September 22 and 24, 2020, our company took part in the 15th International Fair of Welding Technology and Equipment, which took place as part of the Metal Processing Technology Exhibition in Kielce. Together with our partner Technika Spawalnicza from Poznań, we promoted the brands TECNA and BTH.

2023 – an automated line for welding 2D and 3D fence panels was launched at our client’s factory in Lithuania.

2020 – we launched a robotised machine for resistance welding the heat shields of the exhaust system for the Tenneco factory in Mexico.

2019 – we commissioned a station for projection welding of nuts with the car seat support for LEAR Corporation in the Czech Republic.

2018 – we launched two stations for automatic pressing and welding of the ring on the car shock absorber piston rod in factories of BWI Group in China and Mexico. We also supplied BWI Group in Mexico with a station for seam welding of a base cup to the car shock absorber cylinder as well as a station for spring seat pressing and pin resistance welding.

Films of the machines can be found in REALIZATIONS tab.

On the 9-10 of October 2019, our company took part in the 3rd International Seminar: Trends in the development of welding technologies and alternative techniques, organized by the Welding Institute in Gliwice.

We presented our projects in the field of welding and multi-functional devices for the automotive industry and advanced measuring and control systems for the welding process, developed by our company for the needs of the automotive industry.

On 4-7 of June we were present at the Poznan International Fair Trades, where together with our partner Welding Technology from Poznan, we promoted the TECNA and BTH brands.