The tooling for resistance and arc welding stations, manual and robotized, manufactured by SMOLTECH, is designed from scratch by our construction department. Projects are created on the basis of the client’s guidelines, and all details regarding the scope of automation and security systems are confronted with current needs and requirements. The tooling can be equipped with both manual and fully automatic systems of homing and holding of welded details, as well as full or partial control of the presence of details and the position of applied clamps, pneumatic cylinder tensioners and all other moving elements.

Pneumatic drives and clamps from companies such as Destaco, Festo, Emerson, SMC, Metalwork and Tunkers are most often used for automatic tooling work. It is also common to use standard machine parts of such brands as Kipp, Elesa + Ganter or Misumi. To check the presence of details, induction and optical sensors from Turck, Balluff, Cognex, Banner and Keyence are most often used.

The equipment manufactured by our company meets the requirements of Poka-yoke, which means that by properly designing the homing and clamping elements, as well as thanks to the sensorization, the device will not allow welding of details incorrectly positioned in the bases, or allow collision movements of drives and clamps. Thus, the instruments exclude the possibility of errors by the operator.

In accordance with the Kaizen philosophy, our company’s tooling is constantly being improved and improved so as to best optimize production processes, allowing maximization of profits while minimizing the number of production shortages and relieving machine operators as much as possible.

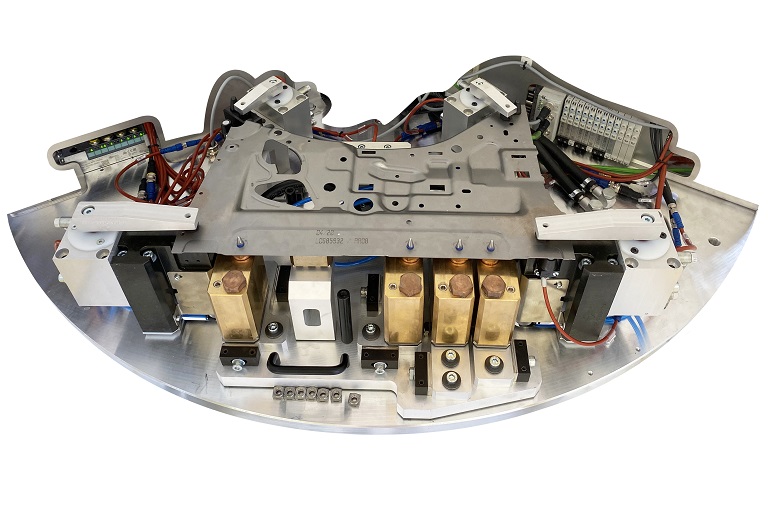

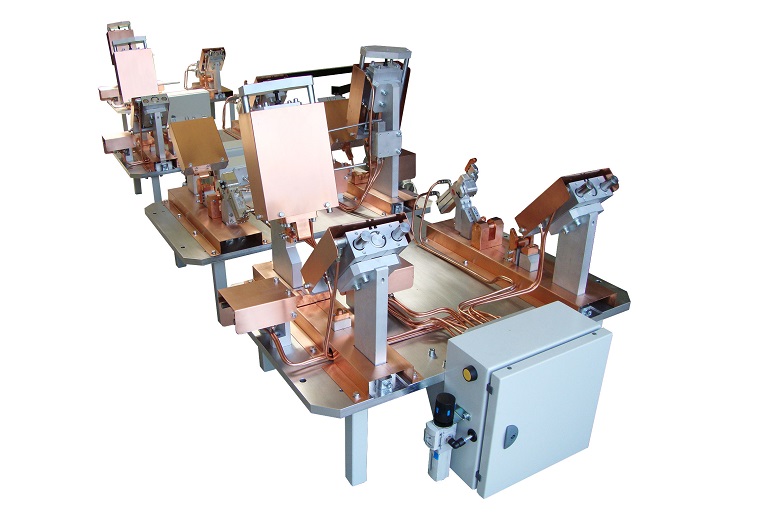

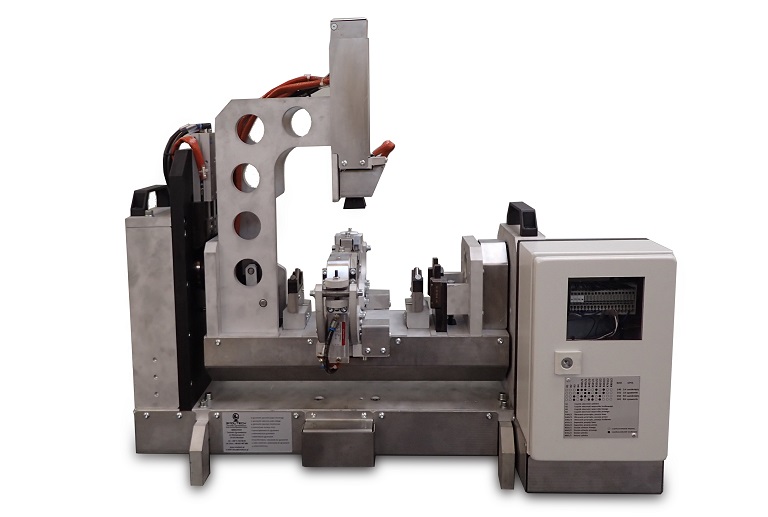

Tooling for a rotary table for resistance welding of nuts.

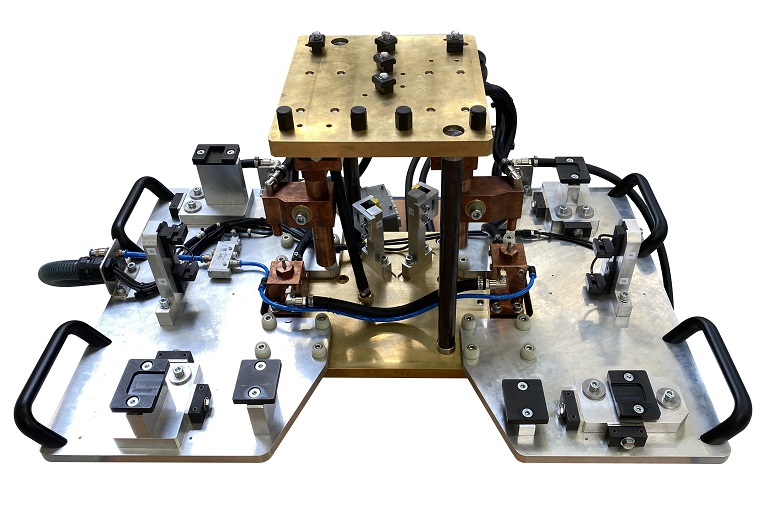

Tooling for welding nuts to a steel stamping for the automotive industry.

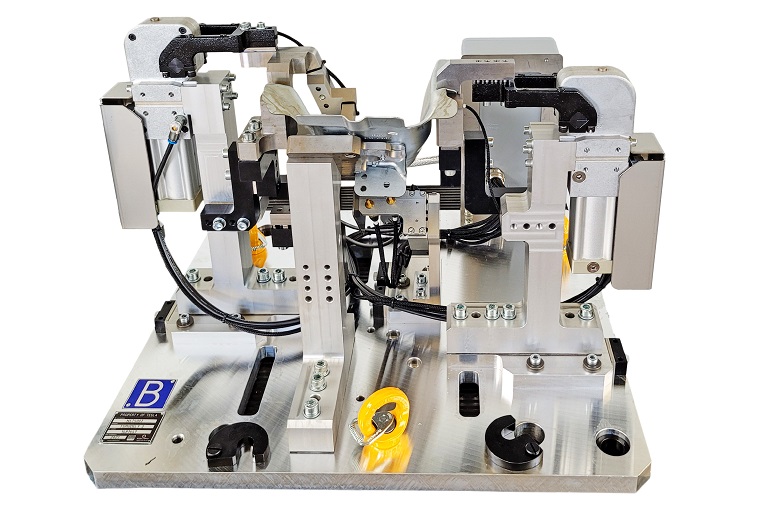

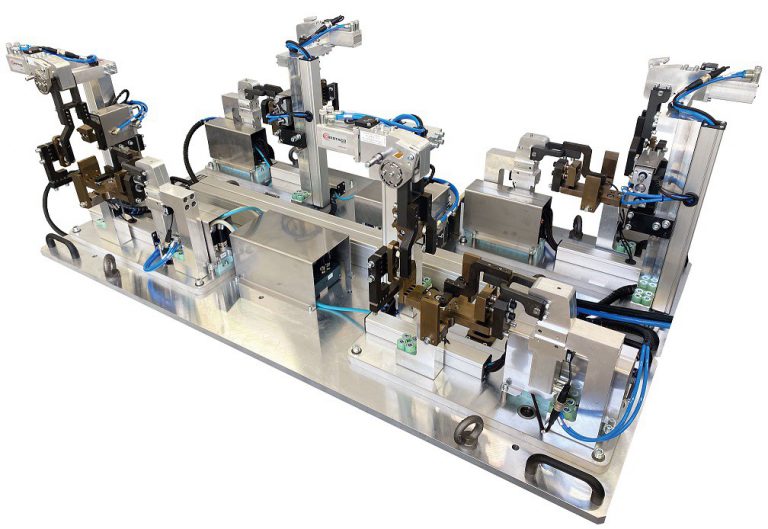

A device for a robotic station for spot welding car body elements.

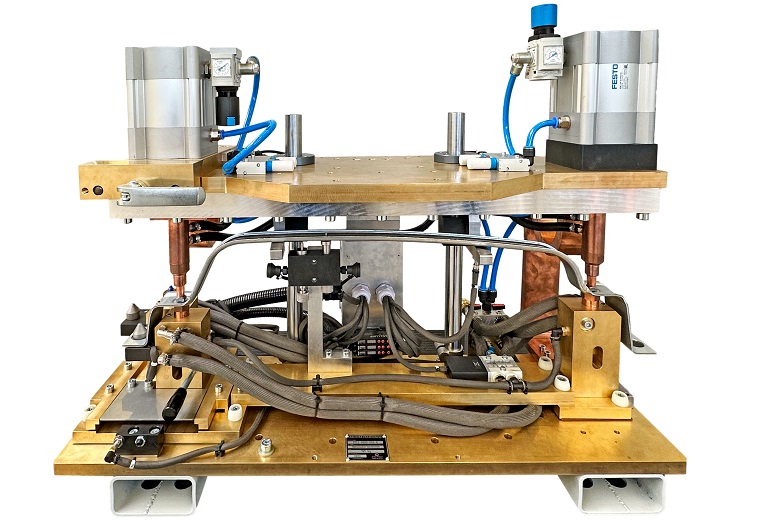

A tool for welding a nut to a fuel tank clamp for the automotive industry.

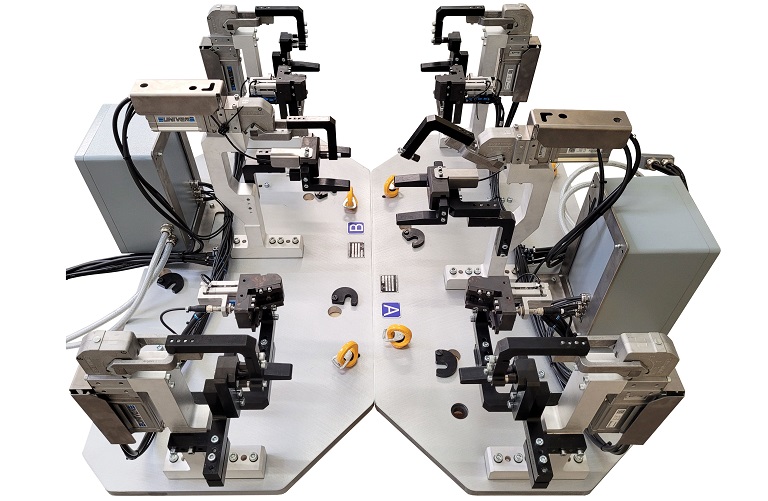

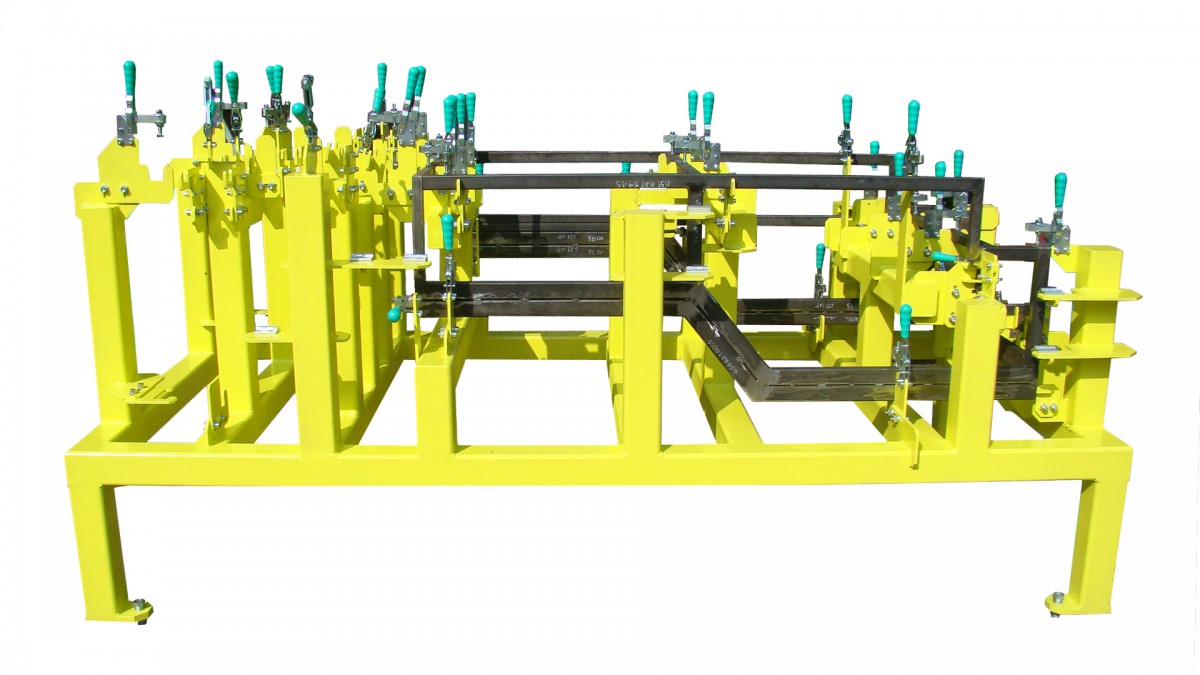

Two-socket device for robotic spot welding of car seat elements.

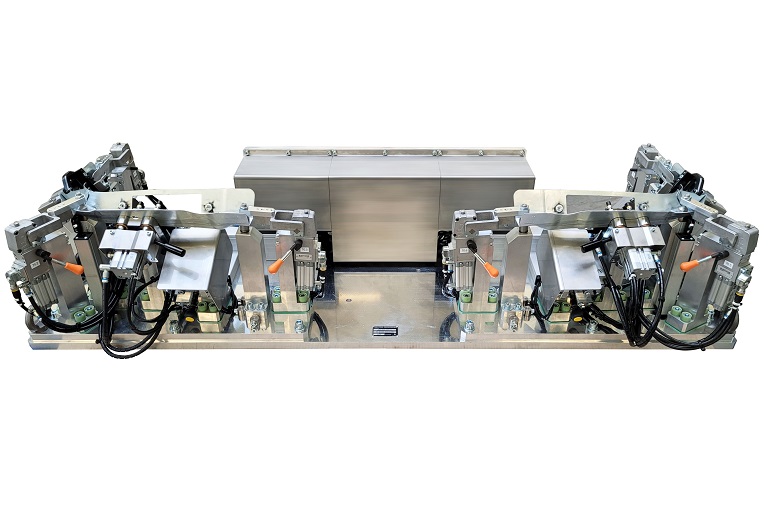

Equipment for spot welding MQB straps for assembly on a robotic station.

Welding device for a robotic station producing car body elements.

Tooling for a robotic welding station for welding car body elements.

A device for a robotic welding station for welding car shock absorber elements.

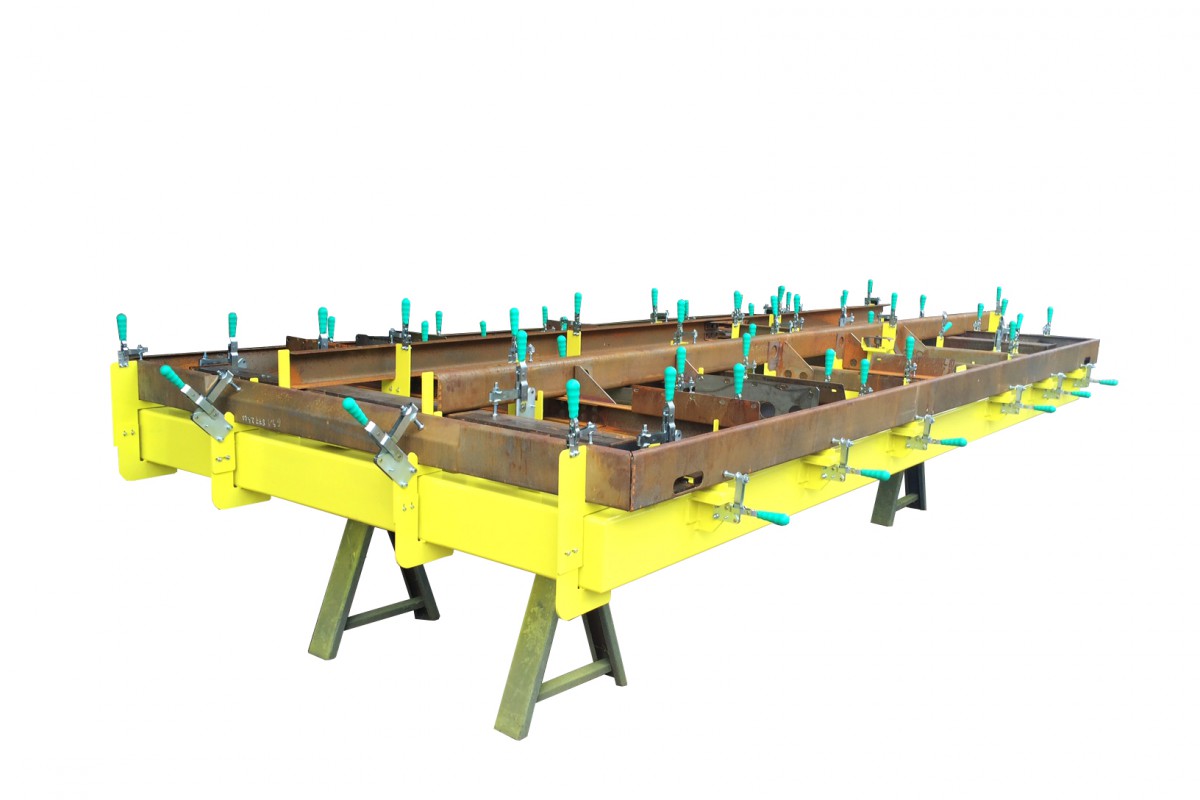

A welding tool for basing truck cabin elements.

A welding device for basing a truck chassis frame.