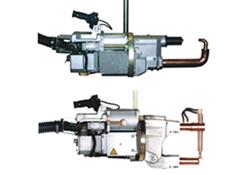

Suspended spot welding machines with an integrated transformer are used for welding elements in spatial or so large and heavy that the use of stationary welders becomes inefficient and non-ergonomic, eg cabinets, cases, enclosures, channels, etc. The smallest machines in this group (2.5-6 kVA) have manual pressure, greater pneumatic pressure by the pushing actuator (models 6-38 kVA) or horizontal pulling (models 38-50 kVA). They use 50 Hz AC transformers or medium frequency inverter MFDCs, e.g. 1000 Hz. Gyroscopic suspension and balancer ensure free movement of the welding machine and minimum effort for the operator. The range allows to choose the optimal model of welder for small repairs as well as industrial production.